Radar Level Transmitters: Advancing Precision and Efficiency in Level Measurement

Radar level transmitters are critical instruments utilized in various industries to measure the level of liquids, solids, and slurries within tanks, vessels, and other storage containers. Employing advanced radar technology, these devices provide accurate and reliable level measurements, enabling industrial processes to run smoothly and efficiently.

In this article, we will explore the functioning, applications, benefits, and future potential of radar level transmitters.

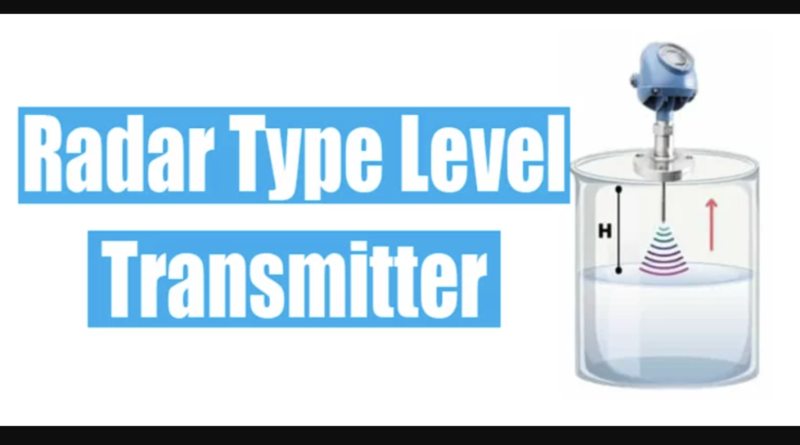

How Radar Level Transmitters Work

Radar level transmitters operate based on the principles of electromagnetic waves. They emit microwave signals towards the surface of the substance being measured, and upon hitting the surface, these signals bounce back to the transmitter.

The time taken for the signal to return to the device is measured, and the distance is calculated using the speed of light. By knowing the container’s height, the level of the substance can be accurately determined.

Different Types of Radar Level Transmitters

There are two primary types of radar level transmitters: guided wave radar (GWR) and non-contact radar.

Guided Wave Radar (GWR):

GWR transmitters use a probe or a waveguide to guide the microwave signal along its length. When the signal encounters the substance’s surface, it reflects back and enables precise level measurement. GWR transmitters are particularly suitable for measuring the level of liquids with low dielectric constants or in applications where foaming or vapor may cause interference.

Non-Contact Radar:

Non-contact radar transmitters, also known as free-space radar, emit signals directly into the tank or vessel without any physical guide. These devices are widely used for liquids and solids with a relatively higher dielectric constant, and they are immune to issues caused by dust, vapor, or varying process conditions.

Applications of Radar Level Transmitters

Radar level transmitters find applications in numerous industries due to their versatility and accuracy. Some of the key areas where these devices are commonly utilized include:

Oil and Gas: In oil refineries and storage tanks, radar level transmitters ensure optimal inventory management and prevent overfilling or underfilling of containers.

Chemical Processing: Radar transmitters monitor chemical levels, aiding in efficient material handling and minimizing the risk of spills or leakage.

Water Treatment: These devices help manage water levels in reservoirs, water towers, and sewage treatment plants, ensuring a stable supply and preventing overflow.

Food and Beverage: In the food industry, radar level transmitters are used to maintain precise ingredient levels during production and storage.

Pharmaceuticals: Accurate level measurements are crucial in pharmaceutical manufacturing to ensure proper quantities and prevent wastage.

Benefits of Radar Level Transmitters

The widespread adoption of radar level transmitters is due to several advantages they offer:

High Accuracy: Radar transmitters provide precise level measurements, even in challenging conditions, such as turbulent surfaces or varying temperatures.

Non-Contact Measurement: Non-contact radar eliminates the need for physical contact with the substance, reducing wear and tear, and minimizing maintenance requirements.

Versatility: These transmitters can measure the level of a wide range of substances, including liquids, solids, and granules.

Reliability: Radar level transmitters are known for their robustness and ability to withstand harsh environmental conditions.

Safety: Accurate level monitoring ensures the prevention of spills, leaks, and potential hazards associated with overfilling.

Future Trends and Innovations

As technology continues to advance, radar level transmitters are likely to see further improvements. Some potential future trends include:

Enhanced Signal Processing: Advancements in signal processing algorithms will lead to even higher accuracy and reliable measurements.

Integration with IoT and Automation: Radar level transmitters are expected to integrate with the Internet of Things (IoT) platforms, enabling remote monitoring and control of levels in real-time.

Multi-Functionality: Future radar transmitters may offer additional features, such as temperature sensing and density measurement.

Conclusion

Radar level transmitters have revolutionized the way industries measure and manage levels of various substances. With their high accuracy, non-contact capabilities, and suitability for diverse applications, they have become indispensable tools for ensuring efficient processes and maintaining safety standards.

As technology continues to evolve, we can expect radar level transmitters to become even more advanced, further optimizing industrial operations worldwide.